Electromagnetic interference can wreak havoc on sensitive electronic systems, causing signal degradation, data corruption, and equipment malfunction. As our world becomes increasingly connected and reliant on electronic devices, protecting electrical signals from unwanted interference has never been more critical.

Shielded wire offers a reliable solution to these challenges. By incorporating protective barriers around conductors, shielded wire maintains signal integrity in environments where electromagnetic interference would otherwise compromise performance. From industrial automation systems to medical equipment, shielded wire ensures that critical communications remain clear and uninterrupted.

This comprehensive guide explores everything you need to know about shielded wire, from understanding different shielding types to selecting the right cable for your specific application. Whether you’re an engineer designing a new system or a technician troubleshooting interference issues, understanding shielded wire fundamentals will help you make informed decisions about cable selection and installation.

What is Shielded Wire?

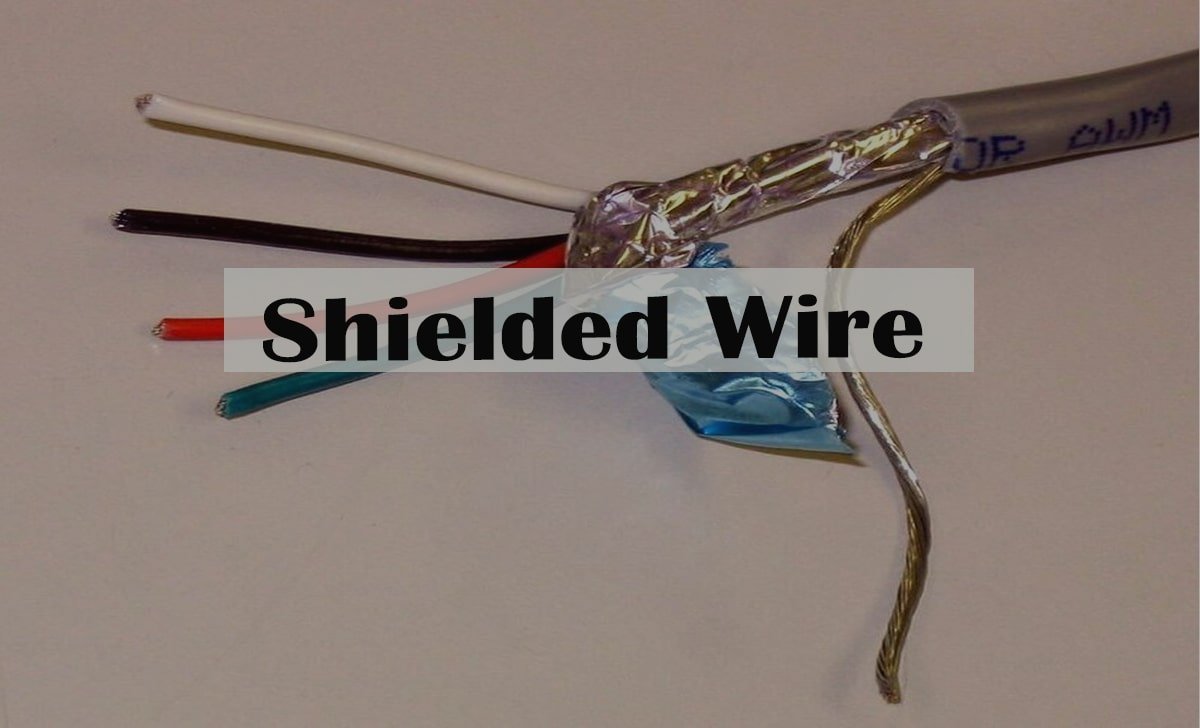

Shielded wire is electrical cable that includes a protective conductive layer surrounding the signal-carrying conductors. This shield acts as a barrier against electromagnetic interference (EMI) and radio frequency interference (RFI), preventing external signals from disrupting the intended electrical transmission.

The shield typically consists of braided copper wire, aluminum foil, or a combination of both materials wrapped around the inner conductors. This conductive barrier creates a Faraday cage effect, redirecting unwanted electromagnetic energy away from the signal path and toward ground.

Unlike standard unshielded wire, shielded cable maintains consistent electrical characteristics even in electrically noisy environments. The shield must be properly grounded to function effectively, creating a low-impedance path for interference currents to flow safely to ground rather than affecting the signal conductors.

Different Types of Shielded Wire

Foil Shielded Wire

Foil shielded wire uses a thin aluminum or copper foil wrapper around the conductors. This lightweight shielding method provides excellent coverage against high-frequency interference while maintaining cable flexibility. Foil shields offer 100% coverage but can be more susceptible to physical damage during installation.

Braided Shield Wire

Braided shield construction weaves fine copper wires into a mesh sleeve around the conductors. This robust shielding method provides superior mechanical protection and better low-frequency interference rejection. Braided shields typically offer 70-95% coverage depending on the braid density and can better withstand repeated flexing.

Combination Shielded Wire

Combination shielding incorporates both foil and braided elements to maximize interference protection. The foil provides complete coverage against high-frequency interference, while the braided layer adds mechanical strength and improves low-frequency shielding effectiveness. This dual-layer approach offers superior performance in demanding applications.

Spiral Shield Wire

Spiral shield construction winds a single conductor or tape in a helical pattern around the cable core. This economical shielding method provides adequate protection for less demanding applications while maintaining good flexibility. However, spiral shields typically offer lower coverage percentages than other shielding types.

Benefits of Using Shielded Wire

Superior Signal Integrity

Shielded wire maintains clean signal transmission by preventing electromagnetic interference from corrupting data. This protection becomes especially important in applications requiring high accuracy or reliability, such as instrumentation and control systems.

Reduced Crosstalk

Multiple conductor shielded cables minimize crosstalk between adjacent signal pairs. The shield prevents signals in one conductor from inducing unwanted voltages in neighboring conductors, maintaining signal clarity in multi-pair applications.

Enhanced System Reliability

By eliminating interference-related malfunctions, shielded wire increases overall system reliability. Equipment operates more consistently when protected from electromagnetic disturbances, reducing downtime and maintenance requirements.

Compliance with Standards

Many industries require shielded wire to meet electromagnetic compatibility (EMC) regulations. Using properly shielded cables helps ensure compliance with FCC, CE, and other regulatory standards governing electromagnetic emissions and immunity.

Extended Transmission Distances

Shielded wire enables longer cable runs without signal degradation. The interference protection allows signals to maintain integrity over greater distances compared to unshielded alternatives.

Applications of Shielded Wire

Industrial Automation

Manufacturing facilities rely on shielded wire to connect sensors, actuators, and control systems. The electrically noisy industrial environment, with motor drives and switching equipment, makes shielding essential for reliable communication between automation components.

Medical Equipment

Hospital and clinical equipment uses shielded wire to ensure accurate readings and patient safety. From MRI machines to patient monitoring systems, shielding prevents interference that could compromise medical measurements or device operation.

Audio and Video Systems

Professional audio/video installations depend on shielded wire to maintain signal quality. Concert venues, recording studios, and broadcast facilities use shielded cables to prevent interference from lighting systems, wireless devices, and other electromagnetic sources.

Computer Networks

Data center and office network installations frequently specify shielded twisted pair (STP) cables for high-speed data transmission. Shielding helps maintain signal integrity in environments with high electromagnetic activity from servers, switches, and wireless devices.

Aerospace and Military

Defense and aerospace applications demand the highest levels of signal protection. Shielded wire meets stringent requirements for reliability and performance in mission-critical systems where interference could have serious consequences.

How to Choose the Right Shielded Wire

Assess Environmental Conditions

Evaluate the electromagnetic environment where the cable will operate. High-interference environments require more robust shielding solutions, while moderate interference levels may only need basic foil shielding.

Consider Frequency Range

Different shielding types provide varying effectiveness across frequency ranges. Foil shields excel at high frequencies, while braided shields perform better at lower frequencies. Combination shields offer broad-spectrum protection.

Evaluate Mechanical Requirements

Applications involving cable movement or vibration need durable braided shields. Stationary installations can utilize less expensive foil shielding without sacrificing performance.

Determine Coverage Requirements

Critical applications may require 100% shield coverage provided by foil shields. Less sensitive applications might accept the 85-95% coverage of braided shields in exchange for better mechanical properties.

Review Standards Compliance

Ensure selected cables meet relevant industry standards for your application. Different sectors have specific requirements for shielding effectiveness, fire resistance, and other performance characteristics.

Installation and Maintenance Tips

Proper Grounding Techniques

Effective shielding requires proper grounding at one or both cable ends, depending on the application. Single-point grounding prevents ground loops, while multi-point grounding may be necessary for long cable runs to maintain shield effectiveness.

Maintain Shield Continuity

Ensure continuous shield connection throughout the cable run, including at connectors and splice points. Any breaks in shield continuity create opportunities for interference to enter the system.

Avoid Shield Damage

Handle shielded cables carefully during installation to prevent shield damage. Damaged shields lose effectiveness and may actually increase interference problems compared to unshielded alternatives.

Separate Power and Signal Cables

Route shielded signal cables away from power cables to minimize interference coupling. When parallel routing is unavoidable, maintain adequate spacing or use additional shielding barriers.

Regular Inspection

Periodically inspect shielded cable installations for physical damage, corrosion, or loose connections. Early detection of problems prevents system failures and maintains optimal performance.

The Future of Shielded Wire

Advancing technology continues to drive shielded wire development. Higher data rates and increased electromagnetic complexity in modern environments demand more sophisticated shielding solutions. Manufacturers are developing new materials and construction techniques to improve shielding effectiveness while reducing weight and cost.

Nanotechnology applications show promise for creating ultra-thin, highly effective shielding materials. These advances could enable more compact cable designs without sacrificing interference protection.

Smart shielding systems that can adapt to changing electromagnetic conditions represent another frontier in cable technology. These intelligent systems could optimize shielding effectiveness automatically based on real-time interference measurements.

Troubleshooting Common Issues

Poor Grounding

Inadequate shield grounding is the most common cause of shielding ineffectiveness. Verify that shield connections provide low-impedance paths to a proper ground reference. Clean corrosion from ground connections and ensure tight mechanical connections.

Shield Discontinuity

Broken or improperly connected shields fail to provide interference protection. Inspect the entire cable run for shield damage, paying particular attention to connector terminations and areas where cables may have been stressed during installation.

Ground Loops

Multiple ground connections can create current loops that actually increase interference. Review grounding scheme to ensure proper single-point or multi-point grounding strategy based on application requirements.

Inadequate Shielding

If interference problems persist despite proper installation, the shielding type may be insufficient for the electromagnetic environment. Consider upgrading to more robust shielding or adding additional protective measures.

Making the Right Choice for Signal Protection

Shielded wire provides essential protection for electronic systems operating in electromagnetically challenging environments. Understanding the different shielding types, their benefits, and proper application techniques enables informed decisions about cable selection and installation.

Success with shielded wire depends on matching the shielding type to application requirements, following proper installation practices, and maintaining shield integrity throughout the system. When properly implemented, shielded wire ensures reliable signal transmission and system performance even in the most demanding electromagnetic environments.

Consider conducting an electromagnetic compatibility assessment of your installation environment to determine optimal shielding requirements. Professional consultation can help identify the most cost-effective shielding solution that meets both performance and budget requirements while ensuring long-term system reliability.

Frequently Asked Questions

Does shielded wire need to be grounded?

Yes, shielded wire must be properly grounded to function effectively. The shield provides a conductive path for interference currents, but this path must connect to ground potential to prevent interference from affecting signal conductors.

Can I use shielded wire outdoors?

Shielded wire can be used outdoors if it has appropriate environmental ratings for moisture, temperature, and UV resistance. Look for cables rated for direct burial or aerial installation depending on your specific outdoor application.

How do I test shielded wire effectiveness?

Shield effectiveness can be measured using specialized RF test equipment to compare signal levels with and without shielding. Visual inspection of shield continuity and ground connections provides basic verification of proper installation.

What’s the difference between shielded and armored cable?

Shielded cable uses thin conductive layers to prevent electromagnetic interference, while armored cable uses thick metallic armor primarily for mechanical protection against physical damage. Some cables incorporate both shielding and armor for comprehensive protection.

Why is my shielded cable still picking up interference?

Common causes include improper grounding, damaged shield, inadequate shielding type for the interference frequency, or ground loops. Systematic troubleshooting of the grounding system and shield continuity usually identifies the problem.