Introduction

Electrical systems power our homes, offices, and industrial facilities, but behind every reliable electrical setup lies a crucial component that often goes unnoticed: the distribution box. This essential piece of equipment serves as the nerve center of your electrical system, managing power flow and protecting circuits from overloads and faults.

Whether you’re a homeowner looking to understand your electrical setup, an electrician seeking comprehensive guidance, or a facility manager planning an upgrade, understanding distribution boxes is vital for electrical safety and efficiency. This guide covers everything from basic components and installation procedures to maintenance tips and emerging technologies.

A well-chosen and properly installed distribution box can prevent electrical hazards, reduce downtime, and ensure your electrical system operates smoothly for years to come. Let’s explore how these critical components work and why they deserve your attention.

What Are Distribution Box and Why They Matter

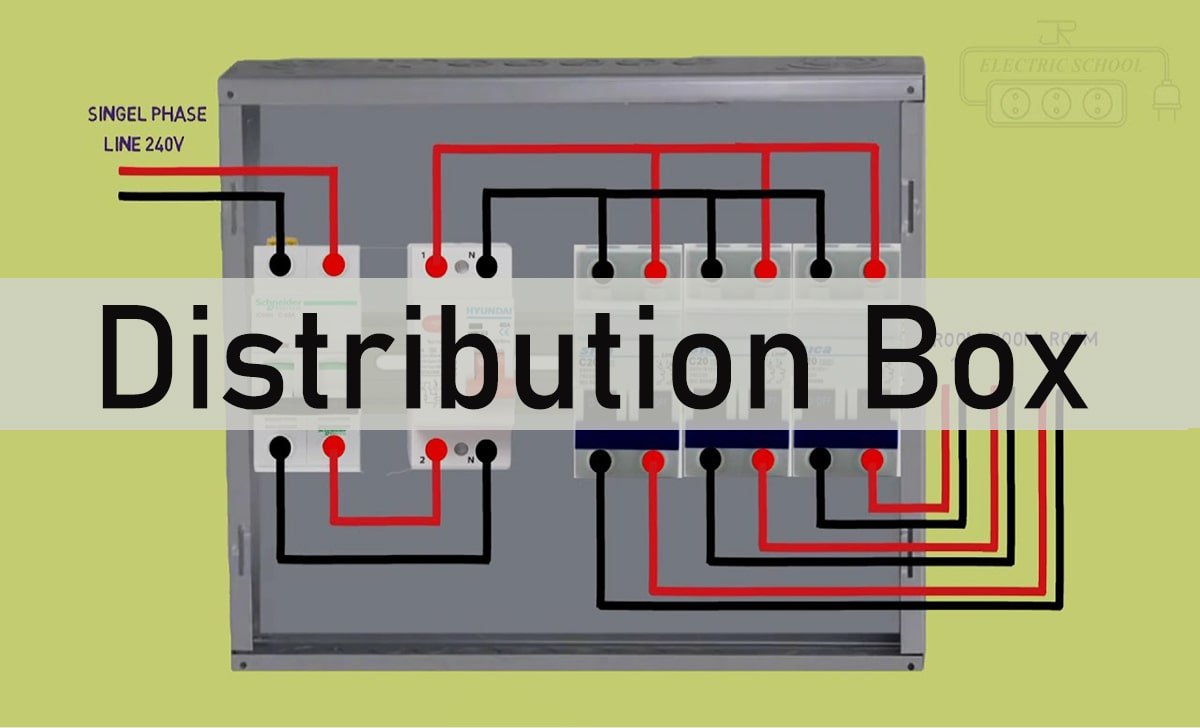

A distribution box, also known as a distribution board, electrical panel, or breaker box, is an enclosure that houses electrical components responsible for distributing electricity throughout a building. It receives power from the main electrical supply and divides it into separate circuits, each protected by circuit breakers or fuses.

The primary purpose of a distribution box is to provide a safe and organized way to control electrical circuits. When an electrical fault occurs, such as an overload or short circuit, the protective devices within the distribution box automatically disconnect the affected circuit, preventing damage to appliances and reducing fire risks.

Modern distribution boxes also serve as monitoring centers, allowing users to quickly identify which circuits are experiencing problems. This centralized approach makes electrical maintenance more efficient and helps ensure compliance with electrical codes and safety standards.

Essential Components of a Distribution Box

Understanding the key components of a distribution box helps you make informed decisions about installation and maintenance. Each element plays a specific role in ensuring safe electrical distribution.

Main Switch

The main switch, or main breaker, controls the entire electrical supply to the distribution box. This large switch allows you to disconnect all power to the building during emergencies or maintenance work. It’s typically rated for the maximum current capacity of the electrical service.

Circuit Breakers

Circuit breakers are automatic switches that protect individual circuits from overcurrent conditions. When too much current flows through a circuit, the breaker trips and interrupts the power flow. Modern circuit breakers reset easily by flipping the switch back to the “on” position after resolving the underlying issue.

Busbars

Busbars are metal strips or bars that distribute electrical power throughout the distribution box. They carry current from the main switch to individual circuit breakers, providing a reliable connection point for all circuits.

Neutral and Earth Bars

These components provide connection points for neutral and earth wires from various circuits. Proper grounding through earth bars is essential for electrical safety, while neutral bars complete the electrical circuit back to the source.

Enclosure

The protective enclosure houses all internal components and prevents accidental contact with live electrical parts. Quality enclosures are made from durable materials like steel or reinforced plastic and meet specific ingress protection ratings for different environments.

Types of Distribution Boxes by Application

Different applications require different types of distribution boxes. Selecting the right type ensures optimal performance and compliance with relevant standards.

Residential Distribution Boxes

Home distribution boxes typically handle single-phase power supplies and contain 6 to 24 circuits. They include standard circuit breakers for lighting, outlets, and major appliances like water heaters and air conditioning units. Residential boxes often feature user-friendly designs with clear circuit labeling.

Commercial Distribution Boxes

Commercial facilities require more robust distribution boxes capable of handling three-phase power and higher current ratings. These boxes often include specialized breakers for equipment like elevators, HVAC systems, and industrial machinery. They may also incorporate monitoring systems for energy management.

Industrial Distribution Boxes

Industrial distribution boxes are built for harsh environments and heavy electrical loads. They feature enhanced protection ratings, multiple voltage levels, and sophisticated control systems. These boxes often include motor protection devices, power factor correction equipment, and remote monitoring capabilities.

Outdoor Distribution Boxes

Designed for weather resistance, outdoor distribution boxes feature sealed enclosures and corrosion-resistant materials. They’re commonly used for street lighting, outdoor events, and temporary power distribution. These boxes must meet strict ingress protection standards to prevent water and dust infiltration.

Step-by-Step Installation Guide

Proper installation of a distribution box requires careful planning and adherence to electrical codes. While major installations should always involve qualified electricians, understanding the process helps ensure quality work.

Pre-Installation Planning

Begin by determining the electrical load requirements and selecting an appropriately sized distribution box. Calculate the total current demand of all circuits and choose a box with adequate capacity for future expansion. Obtain necessary permits and ensure the installation location meets code requirements for accessibility and clearances.

Mounting the Enclosure

Secure the distribution box enclosure to a sturdy surface using appropriate mounting hardware. The box should be level, easily accessible, and positioned at the proper height according to local codes. Ensure adequate clearance around the box for maintenance access.

Connecting the Main Supply

Connect the main electrical supply to the main switch or breaker. This step requires extreme caution and should only be performed by qualified electricians. Proper connection of phase, neutral, and earth conductors is critical for safe operation.

Installing Circuit Breakers

Mount individual circuit breakers in the designated positions within the distribution box. Each breaker should match the current rating and type required for its specific circuit. Ensure proper connection to the busbars and secure mounting to prevent loosening over time.

Circuit Wiring

Connect individual circuits to their respective breakers, ensuring proper wire sizing and termination. Each circuit’s neutral and earth conductors must connect to the appropriate bars. Organize wiring neatly to facilitate future maintenance and troubleshooting.

Testing and Commissioning

After completing all connections, conduct thorough testing to verify proper operation. Test each circuit individually, check for correct voltage levels, and ensure all protective devices function as intended. Document the installation with proper circuit labeling and as-built drawings.

Maintenance Tips for Longevity and Safety

Regular maintenance keeps distribution boxes operating safely and extends their service life. A proactive maintenance approach prevents costly failures and reduces safety risks.

Visual Inspections

Conduct monthly visual inspections to check for signs of overheating, corrosion, or physical damage. Look for discolored components, loose connections, or unusual odors that might indicate problems. Address any concerns promptly to prevent more serious issues.

Connection Tightening

Electrical connections naturally loosen over time due to thermal cycling and vibration. Schedule annual tightening of all connections using proper torque specifications. Loose connections generate heat and can lead to equipment failure or fire hazards.

Cleaning and Dust Removal

Dust and debris accumulation can cause tracking and reduce insulation effectiveness. Clean distribution boxes annually using appropriate methods for the environment. Ensure power is disconnected before cleaning and use only approved cleaning materials.

Testing Protective Devices

Test circuit breakers and other protective devices regularly to ensure they operate correctly. This includes functional testing of trip mechanisms and verification of trip time characteristics. Replace any devices that fail to meet specifications.

Troubleshooting Common Issues

Understanding common distribution box problems helps you identify issues early and take appropriate action. Many problems have simple solutions when caught early.

Frequent Circuit Breaker Tripping

Repeated tripping usually indicates an overloaded circuit or equipment fault. Check for overloaded outlets, damaged appliances, or wiring problems. If the issue persists, consult a qualified electrician to investigate further.

Flickering Lights

Flickering lights may indicate loose connections, overloaded circuits, or voltage fluctuations. Check for loose connections at the distribution box and verify that circuits aren’t overloaded. Persistent flickering requires professional investigation.

Burning Odors

Any burning smell near the distribution box requires immediate attention. Disconnect power if safe to do so and contact a qualified electrician immediately. Burning odors often indicate overheating connections or component failure.

Corrosion and Rust

Moisture infiltration can cause corrosion that compromises electrical safety. Address the moisture source and replace corroded components. Consider upgrading to a higher protection rating enclosure if moisture problems persist.

Benefits of High-Quality Distribution Boxes

Investing in quality distribution boxes provides numerous advantages that justify the higher initial cost through improved performance and reliability.

Quality distribution boxes feature superior materials and construction that withstand harsh operating conditions. They maintain tight manufacturing tolerances, ensuring reliable connections and consistent performance over time. This reduces maintenance requirements and extends service life.

Enhanced safety features in premium distribution boxes include improved arc fault protection, better insulation systems, and more reliable protective devices. These features reduce the risk of electrical accidents and provide better protection for connected equipment.

Quality boxes also offer better expandability and flexibility for future modifications. They typically include additional space for circuit additions and accept a wider range of protective devices and accessories.

Future Trends in Distribution Box Technology

The electrical industry continues to evolve, bringing new technologies that enhance distribution box capabilities and functionality.

Smart distribution boxes integrate digital monitoring and control systems that provide real-time information about electrical consumption, power quality, and equipment status. These systems enable predictive maintenance and help optimize energy usage.

Enhanced communication capabilities allow distribution boxes to integrate with building management systems and smart grid infrastructure. This connectivity enables remote monitoring, automated load management, and improved coordination with renewable energy sources.

Advanced protection technologies incorporate more sophisticated arc fault and ground fault detection systems. These improvements provide better protection against electrical hazards while reducing nuisance tripping.

Modular designs are becoming more common, allowing easier customization and future expansion. These systems support rapid deployment and simplify maintenance by enabling component replacement without complete system shutdown.

Frequently Asked Questions

How often should distribution boxes be inspected?

Distribution boxes should receive visual inspections monthly and comprehensive professional inspections annually. High-usage commercial and industrial installations may require more frequent inspections based on operating conditions and manufacturer recommendations.

Can I add circuits to an existing distribution box?

Circuit additions are possible if the distribution box has adequate capacity and available spaces. However, you must ensure the total load doesn’t exceed the box’s rating and that all additions comply with current electrical codes. Consult a qualified electrician for proper evaluation.

What causes circuit breakers to fail?

Circuit breakers can fail due to age, excessive cycling, moisture exposure, or mechanical damage. Environmental factors like temperature extremes and corrosive atmospheres also contribute to failure. Regular testing helps identify failing breakers before they compromise safety.

How do I choose the right size distribution box?

Size selection depends on the number of circuits needed, current ratings, and future expansion plans. Calculate the total electrical load and add 25% for future growth. Consider physical space requirements and accessibility needs when selecting enclosure size.

What’s the difference between a distribution box and a sub-panel?

A distribution box typically refers to the main electrical panel that receives power from the utility service. A sub-panel is a smaller distribution panel fed from the main panel to serve specific areas or loads. Both serve similar distribution functions but at different system levels.

Making Smart Electrical Infrastructure Decisions

Distribution boxes form the foundation of safe and reliable electrical systems. Understanding their components, installation requirements, and maintenance needs helps you make informed decisions that protect your property and ensure long-term electrical reliability.

Quality distribution boxes represent a wise investment that pays dividends through improved safety, reduced maintenance costs, and enhanced system flexibility. As electrical demands continue to grow and technologies advance, choosing the right distribution solution becomes increasingly important.

Take time to evaluate your current electrical infrastructure and consider whether upgrades could improve safety and performance. Consult with qualified electrical professionals to ensure your distribution boxes meet current standards and can accommodate future needs. Your proactive approach to electrical infrastructure will contribute to safer, more reliable electrical systems for years to come.