Introduction

Air conditioning systems have become essential for comfortable living and working environments. Behind every cooling unit lies a complex network of electrical components working together to regulate temperature and maintain optimal performance. Understanding your aircon circuit can help you identify problems early, perform basic maintenance, and make informed decisions about repairs or upgrades.

This comprehensive guide will walk you through everything you need to know about aircon circuits. From basic components to troubleshooting techniques, you’ll gain the knowledge needed to keep your system running efficiently and safely.

What is an Aircon Circuit?

An aircon circuit refers to the electrical pathway that powers and controls your air conditioning system. This network includes all the electrical components, wiring, and control systems that work together to operate your AC unit effectively.

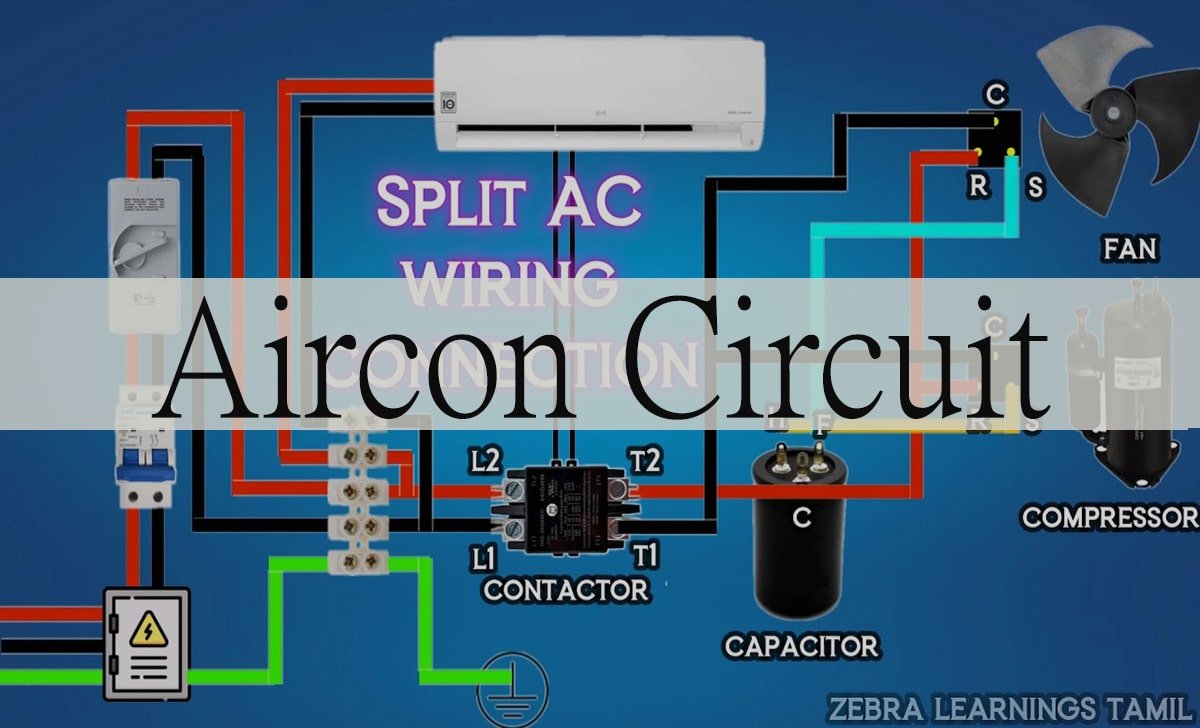

The circuit encompasses both high-voltage components that power major equipment like compressors and fans, as well as low-voltage control circuits that manage thermostats, sensors, and safety switches. These circuits must work in perfect harmony to deliver consistent cooling performance while maintaining safety standards.

Understanding your aircon circuit is crucial because electrical issues account for a significant portion of AC system failures. When you know how these circuits function, you can better maintain your system and communicate effectively with HVAC professionals when repairs are needed.

Key Components of Aircon Circuits

Compressor Circuit

The compressor serves as the heart of your air conditioning system, and its circuit handles the highest electrical load. This component requires substantial power to pressurize refrigerant and maintain the cooling cycle. The compressor circuit includes contactors, capacitors, and overload protection devices that ensure safe operation.

Start capacitors provide the initial boost needed to get the compressor motor running, while run capacitors help maintain efficient operation. These components are critical for proper compressor function and often require replacement as part of regular maintenance.

Fan Motor Circuits

Both indoor and outdoor fan motors have dedicated circuits that control their operation. The outdoor condenser fan helps dissipate heat from the refrigerant, while the indoor blower fan circulates cooled air throughout your space.

These circuits typically include speed controls, thermal protection, and relay switches that coordinate fan operation with other system components. Variable speed motors may have more complex control circuits that adjust fan speed based on cooling demands.

Control Circuits

Low-voltage control circuits manage communication between your thermostat and the main system components. These circuits operate at 24 volts and include safety switches, sensors, and control boards that monitor system performance.

The control circuit receives signals from your thermostat and activates the appropriate components in the correct sequence. This includes turning on the outdoor unit, activating the indoor fan, and monitoring system pressures and temperatures.

Safety and Protection Systems

Modern aircon circuits incorporate multiple safety devices to protect equipment and ensure safe operation. These include pressure switches, temperature sensors, and overload protection that can shut down the system if dangerous conditions are detected.

Ground fault protection and proper circuit breakers provide additional safety measures that protect against electrical hazards. These components are essential for preventing equipment damage and ensuring user safety.

How Aircon Circuits Work

The refrigeration cycle begins when your thermostat calls for cooling and sends a signal through the control circuit. This low-voltage signal activates a relay that energizes the compressor contactor, which then supplies power to the compressor motor.

Simultaneously, the outdoor fan motor circuit activates to provide airflow across the condenser coils. The indoor blower motor receives power through its dedicated circuit, creating airflow across the evaporator coils to distribute cooled air throughout your space.

Throughout this process, various sensors monitor system performance and provide feedback to the control circuit. Temperature sensors ensure proper refrigerant temperatures, while pressure switches monitor system pressures to prevent damage from abnormal operating conditions.

The electrical flow follows a specific sequence to ensure efficient operation. Power flows from your main electrical panel through a dedicated circuit breaker to a disconnect switch near the outdoor unit. From there, it distributes to the various components based on signals from the control circuit.

Troubleshooting Common Circuit Issues

No Power to the Unit

When your AC system doesn’t turn on, start by checking the circuit breaker in your main electrical panel. A tripped breaker is often the culprit and can be reset by switching it off completely before turning it back on.

Next, verify that the outdoor disconnect switch is in the ON position. This safety switch is typically located near the outdoor unit and may have been accidentally turned off during maintenance or cleaning activities.

If power issues persist, check for loose connections at the disconnect switch and ensure all wiring appears intact. However, avoid attempting repairs beyond basic visual inspection, as electrical work requires professional expertise.

Intermittent Operation

Systems that turn on and off frequently may have issues with control circuits or safety switches. Dirty air filters can cause the system to overheat and cycle on thermal protection, creating intermittent operation patterns.

Faulty capacitors often cause intermittent compressor operation. If you hear clicking sounds from the outdoor unit but the compressor doesn’t start consistently, capacitor replacement may be needed.

Control circuit problems can also cause erratic operation. Loose thermostat wires or failing control boards may send inconsistent signals that disrupt normal system operation.

Fan Motor Issues

When outdoor or indoor fans fail to operate, check for power at the motor terminals using appropriate safety procedures. Fan motor failures can result from worn bearings, damaged windings, or electrical connection problems.

Capacitor failure frequently affects fan motor operation. A failing run capacitor may cause the motor to run slowly or not at all, while a bad start capacitor can prevent the motor from starting.

Maintenance Tips for Optimal Circuit Performance

Regular Inspections

Schedule annual professional inspections that include electrical component testing. Technicians can identify potential circuit problems before they cause system failures, saving you money on emergency repairs.

During these inspections, connections are tightened, contactors are cleaned, and capacitors are tested for proper operation. This preventive maintenance significantly extends the life of electrical components.

Keep Components Clean

Dirt and debris can interfere with electrical connections and cause components to overheat. Keep the area around your outdoor unit clean and ensure adequate airflow around electrical components.

Indoor electrical panels should also be kept clean and dry. Moisture can cause corrosion and electrical problems that compromise system performance and safety.

Monitor System Performance

Pay attention to unusual sounds, odors, or operating patterns that might indicate electrical problems. Burning smells, sparking sounds, or frequent cycling can signal developing circuit issues that require professional attention.

Keep track of your system’s energy consumption through your monthly utility bills. Sudden increases in energy usage may indicate electrical problems that are causing inefficient operation.

Upgrading for Enhanced Efficiency

Variable Speed Technology

Modern variable speed motors offer significant efficiency improvements over traditional single-speed units. These motors adjust their speed based on cooling demands, reducing energy consumption and providing better humidity control.

Upgrading to variable speed technology requires compatible control circuits that can manage the more complex motor operations. While the initial investment is higher, the long-term energy savings often justify the upgrade cost.

Smart Controls

Smart thermostats and control systems provide precise temperature control and scheduling capabilities that optimize energy usage. These systems often include diagnostic features that monitor circuit performance and alert you to potential problems.

Advanced control systems can also integrate with home automation platforms, allowing remote monitoring and control of your air conditioning system. This technology helps you identify and address issues quickly, potentially preventing costly repairs.

Energy-Efficient Components

Upgrading to high-efficiency contactors, capacitors, and control boards can improve system reliability and reduce energy consumption. These components are designed to operate more efficiently and typically have longer service lives than standard components.

Consider upgrading to soft-start devices that reduce the electrical demand when your compressor starts. These devices can help prevent voltage drops and reduce stress on electrical components, extending their operational life.

Essential Safety Precautions

Professional Service Requirements

Electrical work on air conditioning systems should always be performed by licensed HVAC technicians or electricians. High-voltage circuits pose serious safety risks, and improper repairs can damage equipment or create fire hazards.

Even basic maintenance tasks like changing air filters should be performed with the system turned off at the thermostat and the main disconnect switch. This simple precaution prevents accidental component activation during maintenance.

Proper Tools and Equipment

If you must perform basic troubleshooting, use appropriate safety equipment including insulated tools and voltage testers. Never assume circuits are de-energized without proper testing using calibrated instruments.

Lockout/tagout procedures should be followed when performing any maintenance that requires accessing electrical components. This involves turning off power at multiple points and securing switches to prevent accidental re-energization.

Emergency Procedures

Know the location of your main electrical panel and outdoor disconnect switch so you can quickly shut off power in emergency situations. If you smell burning odors or see sparks, immediately turn off power and contact a professional service provider.

Keep emergency contact information for qualified HVAC technicians readily available. Electrical emergencies require prompt professional attention to prevent property damage or safety hazards.

Frequently Asked Questions

How often should aircon circuits be inspected?

Professional electrical inspections should be performed annually as part of routine HVAC maintenance. However, you should visually check for obvious problems like loose connections or damaged wiring monthly when changing air filters.

Can I replace aircon circuit components myself?

Most circuit components require professional installation due to safety requirements and local electrical codes. While homeowners can perform basic tasks like thermostat battery replacement, compressor contactors, capacitors, and motor replacements should be handled by licensed technicians.

What causes aircon circuit breakers to trip frequently?

Frequent breaker trips usually indicate electrical problems such as short circuits, ground faults, or overloaded components. Common causes include failing compressor motors, damaged wiring, or faulty contactors that need professional diagnosis and repair.

How long do aircon circuit components typically last?

Contactors and capacitors typically last 5-10 years, while properly maintained motors can operate for 15-20 years. Control boards and thermostats may last 10-15 years, though technological advances often make earlier upgrades beneficial.

What are signs that my aircon circuit needs professional attention?

Warning signs include frequent breaker trips, burning odors, unusual sounds from electrical components, inconsistent system operation, or visible damage to wiring or connections. Any of these symptoms warrant immediate professional evaluation.

Maximizing Your Aircon Circuit’s Potential

Understanding your air conditioning circuit empowers you to make informed decisions about maintenance, troubleshooting, and upgrades. While many repairs require professional expertise, knowledge of how these systems work helps you communicate effectively with service technicians and recognize problems early.

Regular maintenance and prompt attention to electrical issues will extend your system’s life and maintain efficient operation. By following safety precautions and working with qualified professionals, you can ensure your air conditioning system provides reliable comfort for years to come.

Remember that electrical systems require respect and caution. When in doubt, always consult with licensed HVAC professionals who have the training and equipment to handle complex circuit problems safely and effectively.