Introduction

Water damage can destroy even the most well-built structures. From rotting wood frames to compromised insulation, moisture infiltration costs property owners thousands of dollars in repairs every year. The solution lies in proper flashing installation and stainless steel flashing has emerged as the gold standard for long-term protection.

This comprehensive guide explores everything you need to know about stainless steel flashing, from its superior properties to installation best practices. Whether you’re a contractor looking to upgrade your materials or a property owner seeking the most durable waterproofing solution, understanding SS flashing will help you make informed decisions that protect your investment for decades.

Modern building codes increasingly recognize the importance of robust moisture barriers, making high-quality flashing not just a smart choice but often a requirement. Let’s examine why stainless steel flashing outperforms traditional alternatives and how to implement it effectively.

What Is Stainless Steel Flashing?

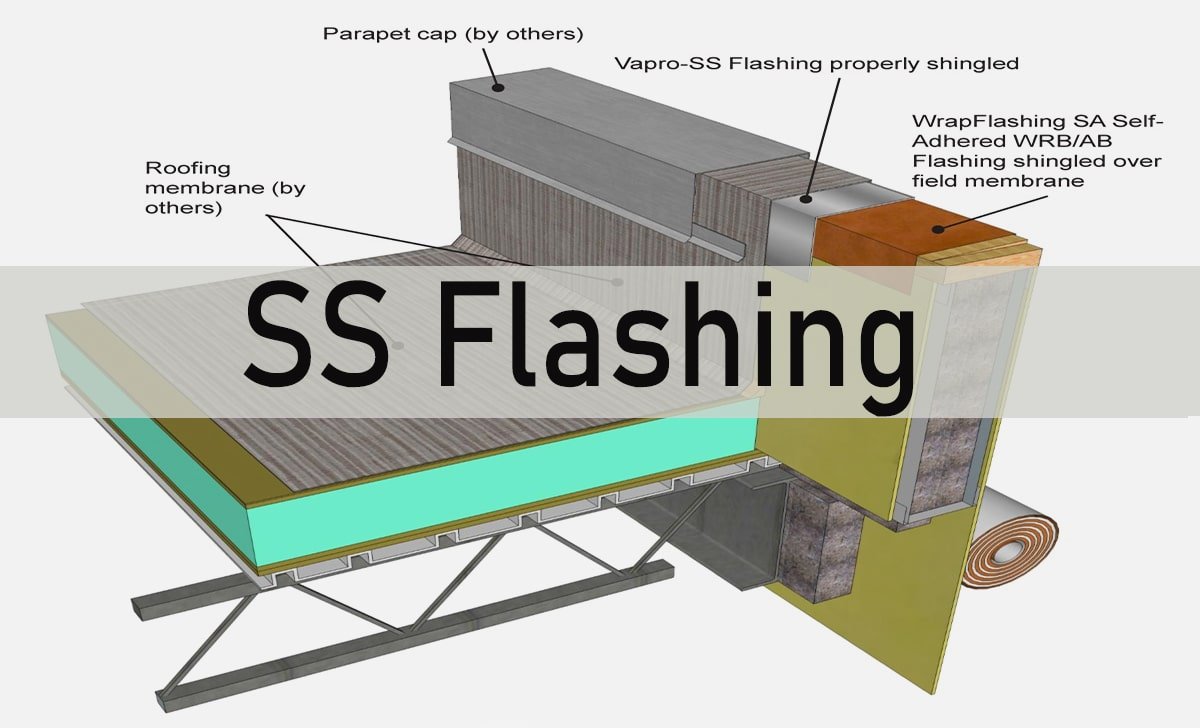

Stainless steel flashing is a thin, corrosion-resistant metal sheet used to direct water away from critical areas of a building’s envelope. Unlike traditional aluminum or galvanized steel options, SS flashing contains chromium and other alloys that form a protective oxide layer, preventing rust and extending service life significantly.

The most common grade used in construction applications is 304 stainless steel, which offers excellent corrosion resistance while remaining cost-effective. This grade contains 18% chromium and 8% nickel, providing the ideal balance of durability and workability for flashing applications.

SS flashing comes in various forms, from basic sheets to innovative composite products. Advanced options like Mighty-Flash™ SA combine the strength of 304 stainless steel with modern adhesive technology, creating self-adhering solutions that simplify installation while maintaining superior performance standards.

Key Benefits of Stainless Steel Flashing

Exceptional Longevity

The primary advantage of SS flashing is its remarkable lifespan. While aluminum flashing may need replacement every 15-20 years, properly installed stainless steel flashing can last 50 years or more. This longevity stems from its inherent corrosion resistance, which prevents the pitting and deterioration common in other metals.

Superior Corrosion Resistance

Stainless steel’s chromium content creates a passive layer that self-heals when scratched, maintaining protection even after minor damage. This property makes SS flashing ideal for coastal environments, industrial areas, and regions with harsh weather conditions where other materials quickly fail.

Fire Safety Compliance

Many SS flashing products meet ASTM E84 Class A fire safety standards, making them suitable for commercial and residential applications with strict fire codes. This fire resistance adds an extra layer of protection beyond waterproofing.

Environmental Benefits

Modern stainless steel flashing often contains significant recycled content—sometimes up to 60%—and remains fully recyclable at the end of its service life. This sustainability factor appeals to green building initiatives and LEED certification requirements.

Types of Stainless Steel Flashing Systems

Traditional Sheet Flashing

Standard SS flashing sheets require separate adhesives or mechanical fasteners for installation. While effective, this approach demands more labor and creates potential failure points where fasteners penetrate the material.

Self-Adhering Systems

Innovation has produced self-adhering SS flashing products that combine metal durability with convenient installation. These systems feature factory-applied adhesives that eliminate the need for additional bonding agents while ensuring consistent adhesion.

Mighty-Flash™ SA exemplifies this technology, featuring a proprietary clear adhesive that won’t drool under UV exposure or high temperatures. The product includes a removable release liner for easy application and should be installed with the white woven material facing outward for optimal performance.

Composite Solutions

Advanced SS flashing products incorporate polymeric fabric layers bonded to stainless steel sheets. This construction provides excellent puncture and tear resistance while maintaining flexibility for field forming around complex architectural details.

Installation Best Practices

Surface Preparation

Proper surface preparation is crucial for SS flashing success. Clean all surfaces thoroughly, removing dust, debris, and any substances that could interfere with adhesion. Ensure surfaces are dry and at appropriate temperatures before installation.

Proper Orientation

When installing composite SS flashing products, pay attention to orientation requirements. Products like Mighty-Flash™ SA must be installed with specific sides facing outward to ensure optimal performance and warranty coverage.

Overlap and Sealing

Create generous overlaps at joints—typically 4-6 inches minimum. Seal all seams properly using compatible sealants to prevent water infiltration. Remember that flashing effectiveness depends on continuous protection along vulnerable areas.

Temperature Considerations

Install SS flashing within manufacturer-recommended temperature ranges. Most products perform best when installed between 40°F and 100°F, though specific requirements may vary by product and adhesive system.

Applications and Use Cases

Roof Penetrations

SS flashing excels around roof penetrations like chimneys, vents, and skylights where water infiltration risks are highest. Its ability to form complex shapes while maintaining waterproof integrity makes it ideal for these challenging applications.

Wall Systems

In wall assemblies, SS flashing protects vulnerable areas like window and door openings, foundation transitions, and material changes. The long-term durability proves especially valuable in these hard-to-access locations.

Commercial and Industrial Buildings

Large commercial structures benefit significantly from SS flashing’s extended service life and reduced maintenance requirements. The initial higher cost is offset by decades of reliable performance and minimal replacement needs.

Sizing and Specifications

SS flashing is available in multiple widths to accommodate various applications. Standard widths include 12″, 16″, 18″, 24″, and 36″, with most products supplied in 60-foot rolls for efficient coverage of long runs.

When selecting width, consider the specific application requirements and local building codes. Wider flashing may be necessary for areas with heavy water exposure or extreme weather conditions.

Cost Considerations and Value

While SS flashing typically costs more upfront than aluminum alternatives, its superior longevity provides exceptional value over the building’s lifetime. Factor in reduced maintenance costs, fewer replacements, and improved reliability when evaluating total cost of ownership.

Many manufacturers offer lifetime warranties on premium SS flashing products, further enhancing their value proposition. These warranties often transfer to subsequent property owners, adding resale value to the building.

Making the Smart Investment in Building Protection

Stainless steel flashing represents a proven investment in long-term building protection. Its combination of durability, corrosion resistance, and fire safety makes it the preferred choice for discerning contractors and property owners who understand the true cost of water damage.

Modern innovations like self-adhering systems have eliminated many traditional installation challenges while maintaining the performance advantages that make SS flashing superior. With proper installation and quality products, you can achieve decades of reliable waterproofing protection.

Consider upgrading your next project to stainless steel flashing. The peace of mind that comes from knowing your building envelope is protected by the most durable materials available is worth the investment. Contact qualified suppliers to discuss specific product options and ensure your flashing system meets both current needs and future performance expectations.